Exploring How To Build A Vacuum Truck

The strong pump that draws air out of the tank is the heart of a vacuum truck. A vacuum force is generated when the air is removed. When the primary and secondary cut-off valves are opened, the vacuum force in the tank attempts to equalize with the outside environment and sucks out any fluids or liquids present. Let us discuss in detail How To Build A Vacuum Truck.

The pressure in the tank would soon equalize if you held the hose and lance up in the air, away from water or other liquids. However, if you lay your lance in a pool of liquid, the liquid rather than air is drawn into the tank.

While this may appear to be a straightforward task, a vacuum truck is a sophisticated industrial vehicle. The vacuum’s performance is determined by elements such as:

- The tank’s and air seals’ quality

- The vacuum pump’s power

- The primary and secondary valves are free of leaks.

- The tank’s, pump’s, and hoses’ resistance to corrosion and degradation

Vacuum Trucks Can Save Lives

However, vacuum trucks are more than just sewers and septic systems. These vehicles have the potential to be extremely beneficial in rescue missions and environmental calamities.

Vacuum trucks are critical for swiftly removing and storing hazardous trash or oil spills, preventing them from polluting the environment or entering local waterways.

In certain cases, vacuum trucks have been brought in to help emergency services with rescue efforts. When a tragedy hits and pits or trenches collapse on employees, emergency services may rely on vacuum tankers to swiftly suck any sludge or dirt from the scene.

Materials You Should Consider For Vacuum Trucks

Long-term performance and lowering maintenance costs are two factors to consider when building your new bespoke vacuum truck.

While there is no such thing as a maintenance-free vehicle, there are design considerations you can make that can help you decrease downtime and improve the longevity of your fleet:

-

Stainless Steel For Vacuum Truck

The most expensive choice, but the one that lasts the longest and is the most resistant to corrosion. For these reasons, it’s a good solution for businesses operating near the shore or in regions where a tank could be exposed to saline conditions.

Because the corrosive-resistant walls of stainless steel are thinner, it allows for a lighter vacuum truck to transport more trash without exceeding gross vehicle weight.

-

Aluminium For Vacuum Truck

This option allows you to transport as much garbage as possible on your vehicle. Aluminium tanks, which are around half of the weight of stainless steel tanks, are excellent for individuals whose major concern is weight. While it lacks the corrosion resistance of stainless steel, it has a good life.

-

Mild Steel For Vacuum Truck

Mild steel is the most expensive metal to use, but it is also the heaviest. Steel tanks are generally made of 14-inch thick steel to prevent corrosion. Steel is the most often used metal for vacuum tanks since it is easily repairable and has a long lifespan.

What Is A Vacuum Truck Used For

Cities frequently employ vacuum trucks, also known as vacuum tankers, to handle large-scale liquid and sludge clean-up, most notably in sewage and septic system maintenance.

They can also be used to suction water and debris leftover following hydro-excavation or drilling activities in industrial and municipal contexts.

Vacuum trucks satisfy the demands of communities and companies that require environmental cleanup, storage tank upkeep, and waste management, from removing mud to expose utility wires to preventing sewer system overloads.

How Does A Vacuum Truck Work

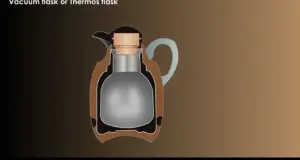

A vacuum truck functions in the same way as a shop vac does. A strong pump draws air out of the holding tank, creating a vacuum inside.

When the primary and secondary cutoff valves on suction hoses are opened, the tank attempts to equalize the pressure within, allowing the truck to suck up liquids and sludges.

Suction power and the capacity to tackle difficult chores are affected by the quality of the equipment and the power of the pump, just as they are with a household vacuum.

Vacuum tanks employed high-pressure hoses, which made them ideal for excavation without causing any harm. A pump is utilized to generate negative air pressure, which provides the vacuum with incredible suction force. The greater the power of the pump, the greater the suction created by the vacuum.

Conclusion

One of the most popular applications for vacuum tankers is the cleaning of septic tanks and sewers. The sewage vacuum tank removes sludge and build-up from the system, allowing it to operate more effectively and preventing backups and flooding.

They’re also utilized to empty portable toilets on construction sites and in the aviation sector. The waste is subsequently securely disposed of into the sewage system. Because of the way the vacuum tanks are built, they may extract and store potentially dangerous waste.