Set Timing On Sbc With Vacuum Advance

How To Set Timing On Sbc With Vacuum Advance? Many enthusiasts avoid discussing vacuum advancement like the plague. Most people condense its apparent aim into a single function—a method to enhance fuel economy.

While vacuum advance can somewhat enhance the economy, it is only one of several possible beneficial impacts that might arise from its capacity to improve overall engine efficiency.

And operating efficiency is something that almost any engine combination, whether mild street-driven or full-race, can benefit from.

Vacuum Testing Timing With Vacuum Advance

There are two methods for testing vacuum advances on cars equipped with distributors. Inductive pickup timing lights are preferred by mechanics.

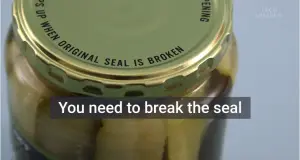

Once the base timing is adjusted correctly, attach a hand-operated vacuum pump to the diaphragm, give it a few pumps, and then use the timing light to observe the timing mark on the crankshaft harmonic balancer progress on the timing scale.

The proper adjustment of a vacuum advance unit is important to ensure that a car engine performs at its best. The vacuum advance mechanism enables the distributor to adjust the spark timing to accommodate the engine’s load and speed needs.

When the engine is under little load, the cylinders burn leaner, requiring the spark to be ignited earlier to get maximum power. This variable spark advance is provided by the vacuum advance unit, which increases fuel economy and throttle responsiveness across the engine’s working range.

Steps To Set Timing On Sbc With Vacuum Advance

- Set the engine’s mechanical timing. Unplug and reconnect the vacuum advance pipe at the distributor, then reconnect the hose. Attach the inductive pickup of the timing light to the No. 1 spark plug wire and the power lines to the car battery.

- Take the distributor hold-down bolt and loosen it. Start the engine and let it warm up to its regular operating temperature.

- Crank the distributor and use the timing lamp to set the timing to the vehicle’s requirements. The timing requirements are usually shown on a sticker in the engine compartment of most automobiles. When all modifications is use, tighten the distributor bolt. Increase the engine speed to 2,000 rpm and have your helper check the balance on the harmonic balancer. Take note of the time option. Reconnect the vacuum advance pipe to the distributor after removing the vacuum advance hose connector.

- At the carburetor, disconnect the vacuum advance hose. Attach the long-hosed vacuum gauge to the vacuum advance port on the throttle. Check that the vacuum gauge hose does not interfere with any of the engine’s functioning elements.

- Drive the car while your assistant or assistance records the greatest amount of suction displayed on the gauge when the engine is running at regular highway speeds.

- Stop the car in a safe location, engage the parking brake, and switch off the engine. Connect the inductive pickup of the timing light to the No. 1 spark plug wire and the power lines to the car battery.

More Steps To Set Timing On Sbc With Vacuum Advance

- Connect the vacuum pump to the distributor vacuum advance using a gauge. Start the engine and instruct your aide to crank it up to 2,000 rpm. Step 5: Increase the vacuum to the reading obtained during the driving test.

- Using the timing light, examine the timing mark on the harmonic balancer. Take note of the overall advance shown on the scale. Subtract the value reported in Step 3 from this reading. For example, if the temperature in Step 3 was 35 degrees and the temperature in Step 8 was 42 degrees, 42 minus 35 = 7.

- Remove the vacuum pump and put a 3/32 Allen wrench further into the vacuum advance port where the hose attaches. The vacuum advance has a tiny adjustable screw. Turn the bolt clockwise to reduce vacuum advance and counter clockwise to enhance vacuum advance. Steps 8 and 9 should be repeat until the immense change between the mechanical advance and vacuum advance readings is around 10 degrees. At regular highway operating circumstances, the vacuum advance is now set to 10 degrees.

Conclusion

For years, amateurs have struggled to determine how much vacuum advance is optimal for a customized engine. They are eager to alter their distributor’s mechanical advance curve to get optimum full efficiency, but they frequently retain the existing vacuum advance canister in place.

And, once linked to a vacuum source, the extra spark advance can produce a rise in the idle speed of several hundred rpm, with carburetor modifications having no impact. Surging at part-throttle or when decelerating is another prevalent ailment, as is run-on during a shutdown.