A Liquid Ring Vacuum Pump Work

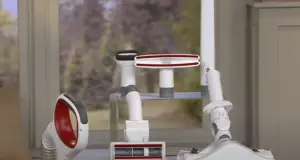

How Does A Liquid Ring Vacuum Pump Work? Liquid ring vacuum pumps are spinning positive displacement equipment that provides process vacuum in chemical, electrical power, environmental, food and beverage processing and packaging, marine, mining, oil and gas, pharmaceutical, pulp and paper, and textiles.

Water or another process-compatible liquid is used as the sealant in liquid ring vacuum pumps. Liquid ring vacuum pumps are a secure and easy solution for managing filthy and potentially harmful gas flows due to their simple functioning and lack of interacting parts. Liquid ring pumps come in single and dual-stage designs and compressor configurations for even more adaptability.

Understanding A Liquid Ring Vacuum Pump And How Does It Work

The liquid at the pump suction port (flange) has a low-pressure value, but the liquid is released from the pump’s outlet pipe (flange) with a massive pressure after flowing through the different pumps impeller steps. LRVPs, unlike centrifugal pumps, draw air out of low-pressure containers, lowering the vessel pressure below atmospheric pressure and creating vacuum conditions.

The main distinction between liquid ring vacuum pumps and other pumps is the impeller, offset from the pump’s centre. As a result, the blades on the top of the pump are closer to the outer wall than those on the side of the pump or at the bottom of the pump. The liquid ring compresses as a consequence of this comparative irregularity.

During a rotation, the eccentricity causes partial filling and then partial emptying of each rotor chamber. This partial filling and emptying movement within each pair of rotor or impeller blades cause a piston action.

Pump components enable gas to enter when the rotor chamber is emptying of liquid and expel gas after the compression is complete.

To achieve a vacuum, liquid ring vacuum pumps generally employ a liquid seal. Water is the most often utilized liquid, which is generally used once and then drained. A cooling water system is frequently used to disperse the heat generated during operation. In this scenario, a part of the liquid in the casing is released with the gas continuously, collected in a separator vessel, and then sent to a heat exchanger. The cooled fluid comes back to the pump casing to eliminate the heat generated by compression.

Features Of Liquid Ring Vacuum Pumps

Allows For Carryover

The pump is unaffected by soft solids, dampness, slugs, chemicals, and other substances. These pollutants will be flushed away by the pump’s exhaust.

Operation That Is Both Cool And Quiet

The circulation of the sealing water inside the pump keeps the pump cool. The operation is quite quiet, with noise levels not surpassing 85 decibels.

For Any Vacuum Level – Constant Operation

The pump can run continuously at any vacuum level, from 29 inches of mercury to atmospheric pressure.

Pump Life Is Increased, And Maintenance Is Easier

Liquid ring vacuum pumps are there to last and feature just one moving element, the rotor, which is place on a shaft and support by a set of bearings intended for continuous operation. This helps the user by reducing wear and making maintenance easier and more economical.

Environmentally Friendly On Ring Vacuum Pump Work

Pumps don’t need an oil change, a filter, oil pans, a condenser, or anything else. As a result, plant rooms are clean, with no oil contamination or oil discharge into drains.

How To Make An LRVP System Work Better On Ring Vacuum Pump Work

Following the guidelines below will enhance the performance of a liquid ring vacuum pump:

- Install solenoid valves on the seal and cooling water supply lines and interlock them with the pump motor. When the pump motor is not operating, this will avoid water waste.

- If the seal liquid temperature is too high, a sealing liquid heat exchanger should be install. Of course, this will raise prices, but it will also increase efficiency.

- Examine the potential of utilizing non-water alternative liquid seals to eliminate wastewater generation and enhance vacuum performance.

Is There A Variety Of Liquid Ring Pumps

While liquid ring pumps have a similar construction, there are two main types of fluid systems:

Once-Through

Water is continually supply into and out of the pump in a once-through system. The cost of water and the expense of water disposal are two big concerns with this system. If the water is pollute, it must be cleanse before being dispose of.

Partial Recovery

Some of the fluid stays in the pump for a lengthy period of time with a partial recovery system. The reservoir continues to feed the pump to replenish it as part of the fluid exits the pump.

Conclusion

Liquid ring vacuum pumps are there in plastics and rubber, medical and pharmaceutical, chemical and petrochemical, electrical power, food and beverage processing and packaging, mining, oil and gas, pulp and paper, and textile industries to provide process vacuum.

To produce a vacuum, liquid ring vacuum pumps generally employ liquid or another suitable liquid sealant.